- 26

- Mar

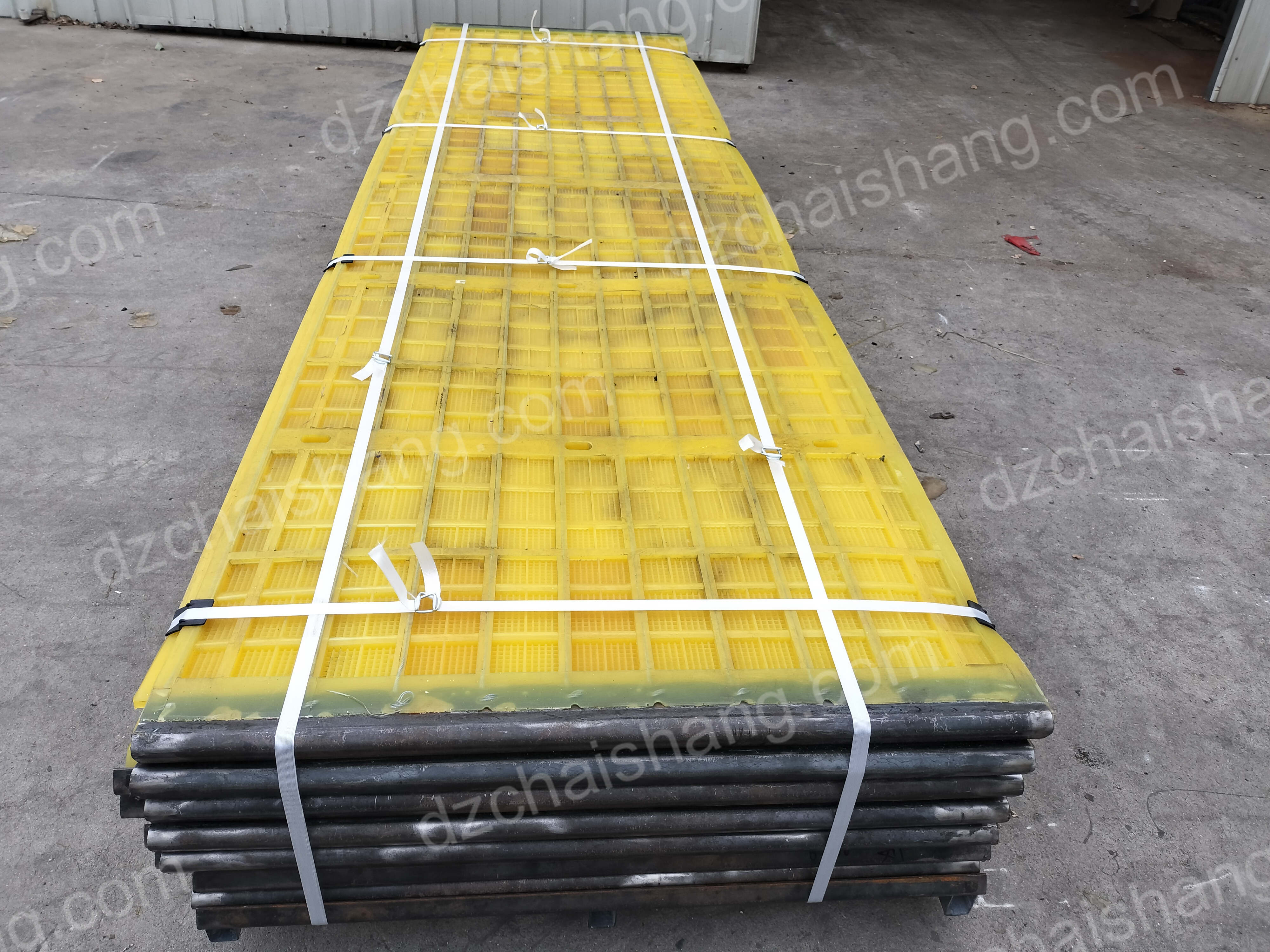

How to store polyurethane screen plates?

Introduction

Polyurethane screen plates are commonly used in various industries for screening and separating materials. Proper storage of these plates is essential to ensure their longevity and effectiveness. Here are some tips on how to store polyurethane screen plates:

1. Store the plates in a cool, dry place away from direct sunlight and extreme temperatures.

2. Avoid stacking the plates on top of each other to prevent warping or deformation.

3. If stacking is necessary, place a protective layer between each plate to prevent scratching or damage.

4. Keep the plates away from sharp objects or rough surfaces that could cause punctures or tears.

5. Regularly inspect the plates for any signs of damage or wear and tear, and address any issues promptly.

6. Consider using a storage rack or shelf specifically designed for polyurethane screen plates to keep them organized and easily accessible.

Proper Storage Techniques for Polyurethane Screen Plates

Polyurethane screen plates are essential components in various industries, including mining, aggregate, and recycling. These durable and versatile plates are designed to withstand harsh conditions and provide efficient screening solutions. However, proper storage is crucial to ensure the longevity and performance of polyurethane screen plates. In this article, we will discuss the best practices for storing polyurethane screen plates to maintain their quality and functionality.

When it comes to storing polyurethane screen plates, the first step is to ensure that they are clean and free from any debris or contaminants. Before storing the plates, it is important to thoroughly clean them with water and a mild detergent to remove any dirt, dust, or residue that may have accumulated during use. Once the plates are clean, allow them to dry completely before storing them to prevent mold or mildew growth.

After cleaning and drying the polyurethane screen plates, the next step is to store them in a cool, dry, and well-ventilated area. It is important to avoid storing the plates in direct sunlight or extreme temperatures, as this can cause the material to degrade over time. Additionally, storing the plates in a humid environment can lead to mold growth and deterioration of the material. Therefore, it is best to store polyurethane screen plates in a climate-controlled environment to maintain their quality.

To prevent damage to the polyurethane screen plates during storage, it is recommended to stack them vertically or horizontally with spacers between each plate. This will help prevent warping or bending of the plates and ensure that they remain flat and intact. Additionally, it is important to avoid stacking heavy objects on top of the plates, as this can cause them to deform or crack.

Another important aspect of storing polyurethane screen plates is to avoid contact with sharp objects or abrasive materials that can cause damage to the surface of the plates. It is best to store the plates in a dedicated storage area away from any potential hazards to ensure their safety and integrity. Additionally, it is important to handle the plates with care when moving or storing them to prevent any accidental damage.

In addition to proper storage techniques, it is also important to regularly inspect the polyurethane screen plates for any signs of wear or damage. If any cracks, tears, or other defects are found, it is important to address them immediately to prevent further deterioration of the plates. Regular maintenance and inspection of the plates will help prolong their lifespan and ensure optimal performance.

In conclusion, proper storage techniques are essential for maintaining the quality and functionality of polyurethane screen plates. By following the guidelines outlined in this article, you can ensure that your plates remain in top condition and provide efficient screening solutions for your industry needs. Remember to clean, dry, and store the plates in a suitable environment, handle them with care, and inspect them regularly for any signs of wear or damage. By taking these steps, you can prolong the lifespan of your polyurethane screen plates and maximize their performance.