- 08

- Apr

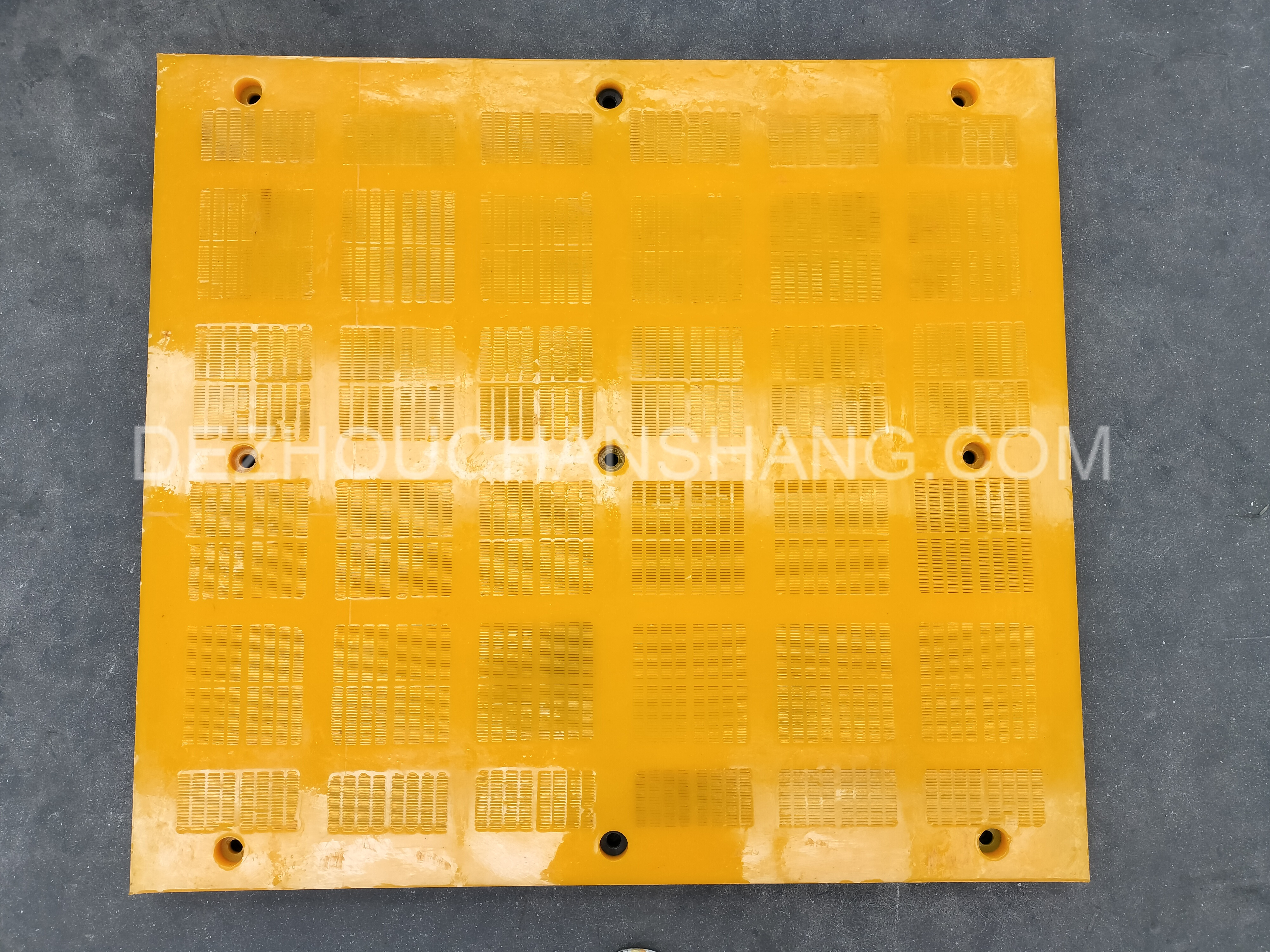

shaker Polyurethane tensioned sieve Manufacture Aggregate

Introduction

Shaker Polyurethane tensioned sieves are commonly used in the aggregate industry for efficient and accurate particle size separation. These sieves are manufactured using high-quality polyurethane material, which offers excellent wear resistance and durability. The tensioned design ensures a tight and secure fit, allowing for consistent and reliable performance in demanding screening applications.

Benefits of Using Polyurethane Tensioned Sieves in Aggregate Manufacturing

Polyurethane tensioned sieves have become increasingly popular in the aggregate manufacturing industry due to their numerous benefits. These sieves are made from high-quality polyurethane material, which offers exceptional durability and longevity compared to traditional wire mesh sieves. In this article, we will explore the advantages of using polyurethane tensioned sieves in aggregate manufacturing.

One of the key benefits of polyurethane tensioned sieves is their superior wear resistance. Polyurethane is a highly durable material that can withstand the harsh conditions of aggregate manufacturing, including abrasive materials and high impact forces. This means that polyurethane tensioned sieves have a longer lifespan than traditional wire mesh sieves, reducing the need for frequent replacements and maintenance.

In addition to their durability, polyurethane tensioned sieves also offer excellent screening efficiency. The tight tensioning of the polyurethane material ensures that the sieve openings remain consistent and do not stretch or deform over time. This results in more accurate and precise screening of aggregate materials, leading to higher quality end products.

Furthermore, polyurethane tensioned sieves are highly resistant to blinding and clogging. The smooth surface of the polyurethane material prevents material buildup and blockages, allowing for continuous and uninterrupted screening operations. This helps to improve overall production efficiency and reduce downtime caused by sieve maintenance.

Another advantage of polyurethane tensioned sieves is their versatility. These sieves can be custom-made to fit a wide range of screening equipment, making them suitable for various applications in the aggregate manufacturing industry. Whether you are screening sand, gravel, or crushed stone, polyurethane tensioned sieves can provide reliable and efficient screening solutions.

Moreover, polyurethane tensioned sieves are easy to install and replace, saving time and labor costs for aggregate manufacturers. The lightweight nature of polyurethane material makes handling and maintenance of these sieves quick and convenient. This allows for faster sieve changes and minimizes production downtime, ultimately increasing overall productivity.

Additionally, polyurethane tensioned sieves are environmentally friendly. Unlike traditional wire mesh sieves, polyurethane material is non-toxic and recyclable, making it a sustainable choice for aggregate manufacturing operations. By using polyurethane tensioned sieves, companies can reduce their environmental impact and contribute to a greener future.

In conclusion, the benefits of using polyurethane tensioned sieves in aggregate manufacturing are clear. From their superior durability and wear resistance to their excellent screening efficiency and versatility, polyurethane tensioned sieves offer a range of advantages that can help improve production processes and increase overall profitability. With their ease of installation and maintenance, as well as their environmentally friendly properties, polyurethane tensioned sieves are a smart choice for any aggregate manufacturer looking to optimize their screening operations.